May 29, 2025

1. Rounding of ductile iron pipes:

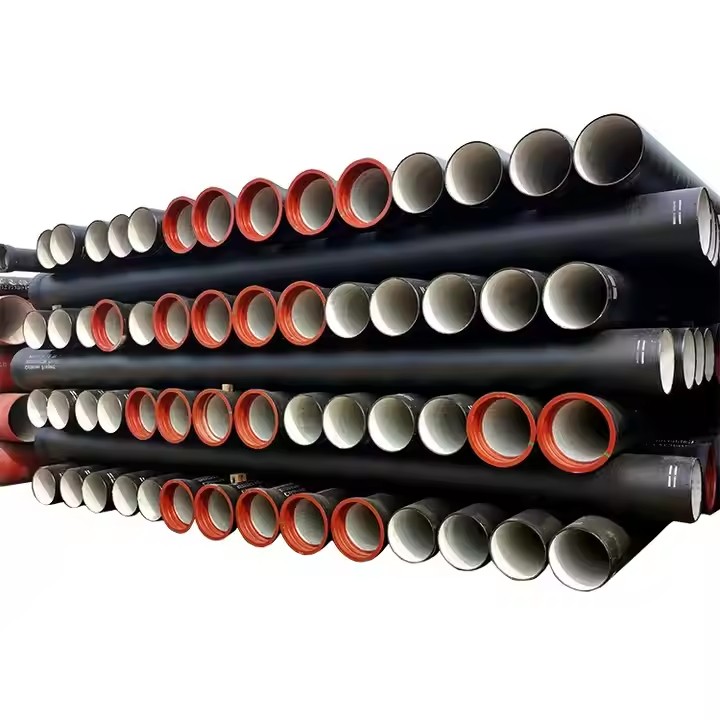

By using hydraulic or mechanical lifting methods, the interior is lifted and pressed outward, or pressure is applied inward from the outer surface of the pipe To prevent damage to the cement mortar lining, hardwood pads similar in shape to the inside of the pipe should be used The external image of rehabilitation ductile iron pipes.

2. Ductile iron pipe cutting:

The grinding wheel used for cutting pipes should be able to install cutting and polishing grinding wheels. Grinding wheels made of silicon carbide are suitable for cutting pipes with cement lining. When cutting pipes, the pipes should be placed on a horizontal ground or square wood. The process of cutting pipes is as follows: marking, cutting, and polishing.

3. External coating repair of ductile iron pipes:

Clean the surface with a brush and wire, and if necessary, use a gas ignition method to clean it. After cleaning with a wire brush, apply paint.

4. Repair of ductile iron pipe lining:

a. Move the repaired part to the bottom and remove the damaged part of the cup.

b. Use a metal brush to remove residual cement blocks, moisten the edges of the cement layer in the area to be repaired, and then wait for a few sections.

c. Fill the cement mortar and press it to the original thickness of the cement coating.

d. The end is to smooth the surface and add some water or cover it with a damp cloth to prevent the cement from drying too quickly and cracking.

Previous: A Brief Discussion on the Performance of Ductile Iron Pipes

Next: Meet Solid at SIEE-POLLUTEC Algeria 2025: Your Trusted Pipeline Specialist at Booth D04

Copyrights © Shanxi Solid Industrial Co., Ltd. All Rights Reserved